Nuclear Power Reactors in the World / IAEA 2023 Edition

ID 22157 | 02.07.2024 / Documenti allegati

IAEA 2023 Edition

This is the 43rd edition of Reference Data Series No. 2, which presents the most recent reactor data available to the IAEA.

It contains summarized information as of the end of 2022 on power reactors operating, under construction and shut down as well as performance data on reactors operating in the IAEA Member States.

The information is collected through designated national correspondents in the Member States and the data are used to maintain the IAEA's Power Reactor Information System (PRIS).

Fonte: IAEA 2024

______

Operable nuclear power reactors worldwide / World Nuclear Association - May 2024

ID 22157 | 02.07.2024 - World Nuclear Association - Download scheda

Number of operable nuclear power reactors worldwide as of May 2024, by country

As of May 2024, there were 440 nuclear reactors in operation in 32 countries around the world. The United States had the largest number of nuclear power reactors in operation at the time, at 94 units. Operable nuclear reactors refer to those that are connected to the grid.

Operation of a nuclear reactor

A nuclear reactor produces and controls the release of energy from splitting the atoms of certain elements. In a nuclear power reactor, the energy released is used as heat to make steam to generate electricity. (In a research reactor the main purpose is to utilize the actual neutrons produced in the core. In most naval reactors, steam drives a turbine directly for propulsion.)

The principles for using nuclear power to produce electricity are the same for most types of reactor. The energy released from continuous fission of the atoms of the fuel is harnessed as heat in either a gas or water, and is used to produce steam. The steam is used to drive the turbines which produce electricity (as in most fossil fuel plants).

The world's first nuclear reactors 'operated' naturally in a uranium deposit about two billion years ago. These were in rich uranium orebodies and moderated by percolating rainwater. The 17 known at Oklo in west Africa, each less than 100 kW thermal, together consumed about six tonnes of uranium. It is assumed that these were not unique worldwide.

Today, reactors derived from designs originally developed for propelling submarines and large naval ships generate about 85% of the world's nuclear electricity. The main design is the pressurized water reactor (PWR) which has water at over 300°C under pressure in its primary cooling/heat transfer circuit, and generates steam in a secondary circuit. The less numerous boiling water reactor (BWR) makes steam in the primary circuit above the reactor core, at similar temperatures and pressure. Both types use water as both coolant and moderator, to slow neutrons. Since water normally boils at 100°C, they have robust steel pressure vessels or tubes to enable the higher operating temperature. (Another type uses heavy water, with deuterium atoms, as moderator. Hence the term ‘light water’ is used to differentiate.)

Components of a nuclear reactor

There are several components common to most types of reactor:

Fuel

Uranium is the basic fuel. Usually pellets of uranium oxide (UO2) are arranged in tubes to form fuel rods. The rods are arranged into fuel assemblies in the reactor core.* In a 1000 MWe class PWR there might be 51,000 fuel rods with over 18 million pellets.

* In a new reactor with new fuel a neutron source is needed to get the reaction going. Usually this is beryllium mixed with polonium, radium or other alpha-emitter. Alpha particles from the decay cause a release of neutrons from the beryllium as it turns to carbon-12. Restarting a reactor with some used fuel may not require this, as there may be enough neutrons to achieve criticality when control rods are removed.

Moderator

Material in the core which slows down the neutrons released from fission so that they cause more fission. It is usually water, but may be heavy water or graphite.

Control rods or blades

These are made with neutron-absorbing material such as cadmium, hafnium or boron, and are inserted or withdrawn from the core to control the rate of reaction, or to halt it.* In some PWR reactors, special control rods are used to enable the core to sustain a low level of power efficiently. (Secondary control systems involve other neutron absorbers, usually boron in the coolant – its concentration can be adjusted over time as the fuel burns up.) PWR control rods are inserted from the top, BWR cruciform blades from the bottom of the core.

* In fission, most of the neutrons are released promptly, but some are delayed. These are crucial in enabling a chain reacting system (or reactor) to be controllable and to be able to be held precisely critical.

Coolant

A fluid circulating through the core so as to transfer the heat from it. In light water reactors the water moderator functions also as primary coolant. Except in BWRs, there is secondary coolant circuit where the water becomes steam. (See also later section on primary coolant characteristics.) A PWR has two to four primary coolant loops with pumps, driven either by steam or electricity – China’s Hualong One design has three, each driven by a 6.6 MW electric motor, with each pump set weighing 110 tonnes.

Pressure vessel or pressure tubes

Usually a robust steel vessel containing the reactor core and moderator/coolant, but it may be a series of tubes holding the fuel and conveying the coolant through the surrounding moderator.

Steam generator

Part of the cooling system of pressurised water reactors (PWR & PHWR) where the high-pressure primary coolant bringing heat from the reactor is used to make steam for the turbine, in a secondary circuit. Essentially a heat exchanger like a motor car radiator.* Reactors have up to six 'loops', each with a steam generator. Since 1980 over 110 PWR reactors have had their steam generators replaced after 20-30 years service, over half of these in the USA.

* These are large heat exchangers for transferring heat from one fluid to another – here from high-pressure primary circuit in PWR to secondary circuit where water turns to steam. Each structure weighs up to 800 tonnes and contains from 300 to 16,000 tubes about 2 cm diameter for the primary coolant, which is radioactive due to nitrogen-16 (N-16, formed by neutron bombardment of oxygen, with half-life of 7 seconds). The secondary water must flow through the support structures for the tubes. The whole thing needs to be designed so that the tubes don't vibrate and fret, operated so that deposits do not build up to impede the flow, and maintained chemically to avoid corrosion. Tubes which fail and leak are plugged, and surplus capacity is designed to allow for this. Leaks can be detected by monitoring N-16 levels in the steam as it leaves the steam generator.

Containment

The structure around the reactor and associated steam generators which is designed to protect it from outside intrusion and to protect those outside from the effects of radiation in case of any serious malfunction inside. It is typically a metre-thick concrete and steel structure.

Newer Russian and some other reactors install core melt localisation devices or 'core catchers' under the pressure vessel to catch any melted core material in the event of a major accident.

There are several different types of reactor as indicated in the following table.

Fuelling a nuclear reactor

Most reactors need to be shut down for refuelling, so that the reactor vessel can be opened up. In this case refuelling is at intervals of 12, 18 or 24 months, when a quarter to a third of the fuel assemblies are replaced with fresh ones. The CANDU and RBMK types have pressure tubes (rather than a pressure vessel enclosing the reactor core) and can be refuelled under load by disconnecting individual pressure tubes. The AGR is also designed for refuelling on-load.

If graphite or heavy water is used as moderator, it is possible to run a power reactor on natural instead of enriched uranium. Natural uranium has the same elemental composition as when it was mined (0.7% U-235, over 99.2% U-238), enriched uranium has had the proportion of the fissile isotope (U-235) increased by a process called enrichment, commonly to 3.5-5.0%. In this case the moderator can be ordinary water, and such reactors are collectively called light water reactors. Because the light water absorbs neutrons as well as slowing them, it is less efficient as a moderator than heavy water or graphite. Some new small reactor designs require high-assay low-enriched uranium fuel, enriched to near 20% U-235.

During operation, some of the U-238 is changed to plutonium, and Pu-239 ends up providing about one-third of the energy from the fuel.

In most reactors the fuel is ceramic uranium oxide (UO2 with a melting point of 2800°C) and most is enriched. The fuel pellets (usually about 1 cm diameter and 1.5 cm long) are typically arranged in a long zirconium alloy (zircaloy) tube to form a fuel rod, the zirconium being hard, corrosion-resistant and transparent to neutrons.* Numerous rods form a fuel assembly, which is an open lattice and can be lifted into and out of the reactor core. In the most common reactors these are about 4 metres long. A BWR fuel assembly may be about 320 kg, a PWR one 655 kg, in which case they hold 183 kg uranium and 460 kgU respectively. In both, about 100 kg of zircaloy is involved.

* Zirconium is an important mineral for nuclear power, where it finds its main use. It is therefore subject to controls on trading. It is normally contaminated with hafnium, a neutron absorber, so very pure 'nuclear grade' Zr is used to make the zircaloy, which is about 98% Zr plus about 1.5% tin, also iron, chromium and sometimes nickel to enhance its strength.

A significant industry initiative is to develop accident-tolerant fuels which are more resistant to melting under conditions such as those in the Fukushima accident, and with the cladding being more resistant to oxidation with hydrogen formation at very high temperatures under such conditions.

Burnable poisons are often used in fuel or coolant to even out the performance of the reactor over time from fresh fuel being loaded to refuelling. These are neutron absorbers which decay under neutron exposure, compensating for the progressive build up of neutron absorbers in the fuel as it is burned, and hence allowing higher fuel burn-up (in terms of GW days per tonne of U)*. The best known is gadolinium, which is a vital ingredient of fuel in naval reactors where installing fresh fuel is very inconvenient, so reactors are designed to run more than a decade between refuellings (full power equivalent – in practice they are not run continuously). Gadolinium is incorporated in the ceramic fuel pellets. An alternative is zirconium diboride integral fuel burnable absorber (IFBA) as a thin coating on normal pellets.

* Average burn-up of fuel used in US reactors has increase to nearly 50 GWd/t, from half that in the 1980s.

Gadolinium, mostly at up to 3g oxide per kilogram of fuel, requires slightly higher fuel enrichment to compensate for it, and also after burn-up of about 17 GWd/t it retains about 4% of its absorbtive effect and does not decrease further. The ZrB2 IFBA burns away more steadily and completely, and has no impact on fuel pellet properties. It is now used in most US reactors and a few in Asia. China has the technology for AP1000 reactors.

Main types of nuclear reactor

Pressurised water reactor (PWR)

This is the most common type, with about 300 operable reactors for power generation and several hundred more employed for naval propulsion. The design of PWRs originated as a submarine power plant. PWRs use ordinary water as both coolant and moderator. The design is distinguished by having a primary cooling circuit which flows through the core of the reactor under very high pressure, and a secondary circuit in which steam is generated to drive the turbine. In Russia these are known as VVER types – water-moderated and -cooled.

A pressurized water reactor (PWR)

Source: World Nuclear Association

A PWR has fuel assemblies of 200-300 rods each, arranged vertically in the core, and a large reactor would have about 150-250 fuel assemblies with 80-100 tonnes of uranium.

Water in the reactor core reaches about 325°C, hence it must be kept under about 150 times atmospheric pressure to prevent it boiling. Pressure is maintained by steam in a pressuriser (see diagram). In the primary cooling circuit the water is also the moderator, and if any of it turned to steam the fission reaction would slow down. This negative feedback effect is one of the safety features of the type. The secondary shutdown system involves adding boron to the primary circuit.

The secondary circuit is under less pressure and the water here boils in the heat exchangers which are thus steam generators. The steam drives the turbine to produce electricity, and is then condensed and returned to the heat exchangers in contact with the primary circuit.

Boiling water reactor (BWR)

This type of reactor has many similarities to the PWR, except that there is only a single circuit in which the water is at lower pressure (about 75 times atmospheric pressure) so that it boils in the core at about 285°C. The reactor is designed to operate with 12-15% of the water in the top part of the core as steam, and hence with less moderating effect and thus efficiency there. BWR units can operate in load-following mode more readily than PWRs.

The steam passes through drier plates (steam separators) above the core and then directly to the turbines, which are thus part of the reactor circuit. Since the water around the core of a reactor is always contaminated with traces of radionuclides, it means that the turbine must be shielded and radiological protection provided during maintenance. The cost of this tends to balance the savings due to the simpler design. Most of the radioactivity in the water is very short-lived*, so the turbine hall can be entered soon after the reactor is shut down.

* mostly N-16, with a 7 second half-life

A BWR fuel assembly comprises 90-100 fuel rods, and there are up to 750 assemblies in a reactor core, holding up to 140 tonnes of uranium. The secondary control system involves restricting water flow through the core so that more steam in the top part reduces moderation.

A boiling water reactor (PWR)

Source: World Nuclear Association

Pressurised heavy water reactor (PHWR)

The PHWR reactor has been developed since the 1950s in Canada as the CANDU, and from 1980s also in India. PHWRs generally use natural uranium (0.7% U-235) oxide as fuel, hence needs a more efficient moderator, in this case heavy water (D2O).** The PHWR produces more energy per kilogram of mined uranium than other designs, but also produces a much larger amount of used fuel per unit output.

** with the CANDU system, the moderator is enriched (i.e. water) rather than the fuel – a cost trade-off.

The moderator is in a large tank called a calandria, penetrated by several hundred horizontal pressure tubes which form channels for the fuel, cooled by a flow of heavy water under high pressure (about 100 times atmospheric pressure) in the primary cooling circuit, typically reaching 290°C. As in the PWR, the primary coolant generates steam in a secondary circuit to drive the turbines. The pressure tube design means that the reactor can be refuelled progressively without shutting down, by isolating individual pressure tubes from the cooling circuit. It is also less costly to build than designs with a large pressure vessel, but the tubes have not proved as durable.

A pressurized heavy water reactor (PWR)

Source: World Nuclear Association

A CANDU fuel assembly consists of a bundle of 37 half metre long fuel rods (ceramic fuel pellets in zircaloy tubes) plus a support structure, with 12 bundles lying end to end in a fuel channel. Control rods penetrate the calandria vertically, and a secondary shutdown system involves adding gadolinium to the moderator. The heavy water moderator circulating through the body of the calandria vessel also yields some heat (though this circuit is not shown on the diagram above).

Newer PHWR designs such as the Advanced Candu Reactor (ACR) have light water cooling and slightly-enriched fuel.

CANDU reactors can accept a variety of fuels. They may be run on recycled uranium from reprocessing LWR used fuel, or a blend of this and depleted uranium left over from enrichment plants. About 4000 MWe of PWR might then fuel 1000 MWe of CANDU capacity, with addition of depleted uranium. Thorium may also be used in fuel.

Advanced gas-cooled reactor (AGR)

These are the second generation of British gas-cooled reactors, using graphite moderator and carbon dioxide as primary coolant. The fuel is uranium oxide pellets, enriched to 2.5 - 3.5%, in stainless steel tubes. The carbon dioxide circulates through the core, reaching 650°C and then past steam generator tubes outside it, but still inside the concrete and steel pressure vessel (hence 'integral' design). Control rods penetrate the moderator and a secondary shutdown system involves injecting nitrogen to the coolant. The high temperature gives it a high thermal efficiency – about 41%. Refuelling can be on-load.

An advanced gas-cooled reactor (AGR)

Source: World Nuclear Association

The AGR was developed from the Magnox reactor. Magnox reactors were also graphite moderated and CO2 cooled, used natural uranium fuel in metal form, and water as secondary coolant. The UK's last Magnox reactor closed at the end of 2015.

Light water graphite-moderated reactor (LWGR)

The main LWGR design is the RBMK, a Soviet design, developed from plutonium production reactors. It employs long (7 metre) vertical pressure tubes running through graphite moderator, and is cooled by water, which is allowed to boil in the core at 290°C and at about 6.9 MPa, much as in a BWR. Fuel is low-enriched uranium oxide made up into fuel assemblies 3.5 metres long. With moderation largely due to the fixed graphite, excess boiling simply reduces the cooling and neutron absorbtion without inhibiting the fission reaction, and a positive feedback problem can arise, which is why they have never been built outside the Soviet Union. See appendix on RBMK Reactors for further information.

Fast neutron reactor (FNR)

Some reactors do not have a moderator and utilise fast neutrons, generating power from plutonium while making more of it from the U-238 isotope in or around the fuel. While they get more than 60 times as much energy from the original uranium compared with normal reactors, they are expensive to build. Further development of them is likely in the next decade, and the main designs expected to be built in two decades are FNRs. If they are configured to produce more fissile material (plutonium) than they consume they are called fast breeder reactors (FBR).

Operable nuclear power plants

|

Reactor type |

Main countries |

Number |

GWe |

Fuel |

Coolant |

Moderator |

|

Pressurized water reactor (PWR) |

USA, France, Japan, |

310 |

296.5 |

enriched UO2 |

water |

water |

|

Boiling water reactor (BWR) |

USA, Japan, Sweden |

60 |

60.9 |

enriched UO2 |

water |

water |

|

Pressurized heavy water reactor (PHWR) |

Canada, India |

48 |

25.0 |

natural UO2 |

heavy water |

heavy water |

|

Light water graphite reactor (LWGR) |

Russia |

10 |

6.5 |

enriched UO2 |

water |

graphite |

|

Advanced gas-cooled reactor (AGR) |

UK |

8 |

4.7 |

natural U (metal), |

CO2 |

graphite |

|

Fast neutron reactor (FNR) |

Russia |

2 |

1.4 |

PuO2 and UO2 |

liquid sodium |

none |

|

High temperature gas-cooled reactor (HTGR) |

China |

1 |

0.2 |

enriched UO2 |

helium |

graphite |

Advanced reactors

Several generations of reactors are commonly distinguished. Generation I reactors were developed in the 1950-60s and the last one (Wylfa 1 in the UK) shut down at the end of 2015. They mostly used natural uranium fuel and used graphite as moderator. Generation II reactors are typified by the present US fleet and most in operation elsewhere. They typically use enriched uranium fuel and are mostly cooled and moderated by water. Generation III are the advanced reactors evolved from these, the first few of which are in operation in Japan, China, Russia and the UAE. Others are under construction and ready to be ordered. They are developments of the second generation with enhanced safety. There is no clear distinction between Generation II and Generation III.

Generation IV designs are still on the drawing board. They will tend to have closed fuel cycles and burn the long-lived actinides now forming part of spent fuel, so that fission products are the only high-level waste. Of seven designs under development with international collaboration, four or five will be fast neutron reactors. Four will use fluoride or liquid metal coolants, hence operate at low pressure. Two will be gas-cooled. Most will run at much higher temperatures than today’s water-cooled reactors.

More than a dozen (Generation III) advanced reactor designs are in various stages of development. Some are evolutionary from the PWR, BWR and CANDU designs above, some are more radical departures. The former include the Advanced Boiling Water Reactor, a few of which are now operating with others under construction. Advanced PWRs operate in China, Russia and UAE, with more under construction. The best-known radical new design has the fuel as large 'pebbles' and uses helium as coolant, at very high temperature, possibly to drive a turbine directly.

Considering the closed fuel cycle, Generation I-III reactors recycle plutonium (and possibly uranium), while Generation IV are expected to have full actinide recycle.

Many advanced reactor designs are for small units – under 300 MWe – and in the category of small modular reactors (SMRs), since several of them together may comprise a large power plant, maybe built progressively. Apart from the normal oxide fuels, other fuel types are metal, TRISO*, carbide, nitride, or liquid salt.

* TRISO (tristructural-isotropic) particles less than a millimetre in diameter. Each has a kernel (c. 0.5 mm) of uranium oxycarbide (or uranium dioxide), with the uranium enriched up to 20% U-235. This kernel is surrounded by layers of carbon and silicon carbide, giving a containment for fission products which is stable to over 1600°C.

Floating nuclear power plants

Apart from over 200 nuclear reactors powering various kinds of ships, Rosatom in Russia has set up a subsidiary to supply floating nuclear power plants ranging in size from 70 to 600 MWe. These will be mounted in pairs on a large barge, which will be permanently moored where it is needed to supply power and possibly some desalination to a shore settlement or industrial complex. The first has two 40 MWe reactors based on those in icebreakers and operates at a remote site in Siberia. Electricity cost is expected to be much lower than from present alternatives.

The Russian KLT-40S is a reactor well proven in icebreakers. Here a 150 MWt unit produces 35 MWe (gross) as well as up to 35 MW of heat for desalination or district heating. These are designed to run 3-4 years between refuelling and it is envisaged that they will be operated in pairs to allow for outages, with on-board refuelling capability and used fuel storage. At the end of a 12-year operating cycle the whole plant is taken to a central facility for two-year overhaul and removal of used fuel, before being returned to service.

Second generation Russian FNPPs will have two 175 MWt, 50 MWe RITM-200M reactor units, each about 1500 tonnes lighter but more powerful than KLT-40S, and thus on a much smaller barge – about 12,000 rather than 21,000 tonnes displacement. Refuelling will be every 10-12 years. Very similar RITM-200 reactors power the latest Russian icebreakers. In December 2022 Rosatom announced that it had developed nuclear fuel for the RITM-200s.

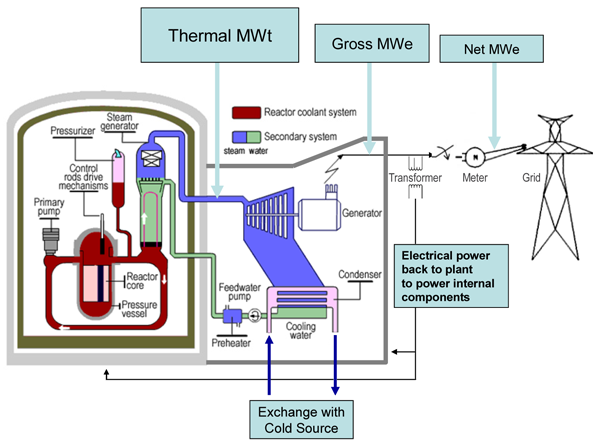

Power rating of a nuclear reactor

Nuclear plant reactor power outputs are quoted in three ways:

- Thermal MWt, which depends on the design of the actual nuclear reactor itself, and relates to the quantity and quality of the steam it produces.

- Gross electrical MWe, which indicates the power produced by the attached steam turbine and generator, and also takes into account the ambient temperature for the condenser circuit (cooler means more electric power, warmer means less). Rated gross power assumes certain conditions with both.

- Net electrical MWe, which is the power available to be sent out from the plant to the grid, after deducting the electrical power needed to run the reactor (cooling and feedwater pumps, etc.) and the rest of the plant.*

* Net electrical MWe and gross MWe vary slightly from summer to winter, so normally the lower summer figure, or an average figure, is used. If the summer figure is quoted, plants may show a capacity factor greater than 100% in cooler times. Watts Bar PWR in Tennessee is reported to run at about 1125 MWe in summer and about 1165 MWe net in winter, due to different condenser cooling water temperatures. Some design options, such as powering the main large feedwater pumps with electric motors (as in EPR or Hualong One) rather than steam turbines (taking steam before it gets to the main turbine-generator), explains some gross to net differences between different reactor types. The EPR has a relatively large drop from gross to net MWe for this reason, and as noted above, the Hualong One needs 20 MWe to run its primary pumps.

Gross, thermal and net power generation from nuclear power plants

Source: World Nuclear Association

The relationship between these is expressed in two ways:

- Thermal efficiency %, the ratio of gross MWe to MWt. This relates to the difference in temperature between the steam from the reactor and the cooling water. It is often 33-37% in light water reactors, reaching 38% in the latest PWRs.

- Net efficiency %, the ratio of net MWe achieved to MWt. This is a little lower, and allows for plant usage.

In World Nuclear Association information pages and figures and World Nuclear News items, generally net MWe is used for operating plants, and gross MWe for those under construction or planned/proposed.

Lifetime of nuclear reactors

Most of today's nuclear plants which were originally designed for 30 or 40-year operating lives. However, with major investments in systems, structures and components operating lifetimes can be extended, and in several countries there are active programmes to extend operation. In the USA nearly all of the almost 100 reactors have been granted operating licence extensions from 40 to 60 years. This justifies significant capital expenditure in upgrading systems and components, including building in extra performance margins. Some will operate for 80 years or more.

Some components simply wear out, corrode or degrade to a low level of efficiency. These need to be replaced. Steam generators are the most prominent and expensive of these, and many have been replaced after about 30 years where the reactor otherwise has the prospect of running for 60 or more years. This is essentially an economic decision. Lesser components are more straightforward to replace as they age. In Candu reactors, pressure tube replacement has been undertaken on some plants after about 30 years of operation.

A second issue is that of obsolescence. For instance, older reactors have analogue instrument and control systems. Some have been replaced with digital systems. Thirdly, the properties of materials may degrade with age, particularly with heat and neutron irradiation. In respect to all these aspects, investment is needed to maintain reliability and safety. Also, periodic safety reviews are undertaken on older plants in line with international safety conventions and principles to ensure that safety margins are maintained.

Another important issue is knowledge management over the full lifecycle from design, through construction and operation to decommissioning for reactors and other facilities. This may span a century and involve several countries, and involve a succession of companies. The plant lifespan will cover several generations of engineers. Data needs to be transferable across several generations of software and IT hardware, as well as being shared with other operators of similar plants.* Significant modifications may be made to the design over the life of the plant, so original documentation is not sufficient, and loss of design base knowledge can have huge implications (e.g. Pickering A and Bruce A in Ontario). Knowledge management is often a shared responsibility and is essential for effective decision-making and the achievement of plant safety and economics.

* ISO 15926 covers portability and interoperability for lifecycle open data standard. Also EPRI in 2013 published Advanced Nuclear Technology: New Nuclear Power Plant Information Handover Guide.

Primary coolants

The advent of some of the designs mentioned above provides opportunity to review the various primary heat transfer fluids used in nuclear reactors. There is a wide variety – gas, water, light metal, heavy metal and salt:

Water or heavy water must be maintained at very high pressure (1000-2200 psi, 7-15 MPa, 150 atmospheres) to enable it to function well above 100°C, up to 345°C, as in present reactors. This has a major influence on reactor engineering. However, supercritical water around 25 MPa can give 45% thermal efficiency – as at some fossil-fuel power plants today with outlet temperatures of 600°C, and at ultra supercritical levels (30+ MPa) 50% may be attained.

Water cooling of steam condensers is fairly standard in power plants because it works very well, is relatively inexpensive, and there is a huge experience base. Water (at 75 atm pressure) has good heat capacity – about 4000 kJ/m3 – so is a lot more effective than gas for removing heat, though its thermal conductivity is less than liquid alternatives.

A possible variation on this is having a high proportion of heavy water in the coolant early in the fuel cycle so that more Pu-239 is bred from U-238, thereby extending the cycle and improving uranium utilization. This is known as spectral shift control.

Helium must be used at similar pressure (1000-2000 psi, 7-14 MPa) to maintain sufficient density for efficient operation. However, even at 75 atm pressure its heat capacity is only about 20 kJ/m3. Again, there are engineering implications from the high pressure required, but it can be used in the Brayton cycle to drive a turbine directly.

Carbon dioxide was used in early British reactors, and their current AGRs, which operate at much higher temperatures than light water reactors. It is denser than helium and thus likely to give better thermal conversion efficiency. It also leaks less readily than helium. But at very high temperatures – such as in HTRs – it breaks down, hence the focus on helium. There is now interest in supercritical CO2 for the Brayton cycle.

Sodium, as normally used in fast neutron reactors at around 550ºC, melts at 98°C and boils at 883°C at atmospheric pressure, so despite the need to keep it dry the engineering required to contain it is relatively modest. It has high thermal conductivity and high heat capacity – about 1000 kJ/m3 at 2 atm pressure. However, normally water/steam is used in the secondary circuit to drive a turbine (Rankine cycle) at lower thermal efficiency than the Brayton cycle. In some designs sodium is in a secondary circuit to steam generators. Sodium does not corrode the metals used in the fuel cladding or primary circuit, nor the fuel itself if there is cladding damage, but it is very reactive generally. In particular it reacts exothermically with water or steam to liberate hydrogen. It burns in air, but much less vigorously. Sodium has a low neutron capture cross-section, but it is enough for some Na-23 to become Na-24, which is a beta-emitter and very gamma-active with 15-hour half-life, so some shielding is required. In a large reactor, with about 5000 t sodium per GWe, Na-24 activity reaches an equilibrium level of nearly 1 TBq/kg – a large radioactive inventory. If a reactor needs to be shut down frequently, NaK eutectic which is liquid at room temperature (about 13°C) may be used as coolant, but the potassium is pyrophoric, which increases the hazard. Sodium is about six times more transparent to neutrons than lead.

Lead or lead-bismuth eutectic in fast neutron reactors are capable of higher temperature operation at atmospheric pressure. They are transparent to neutrons, aiding efficiency due to greater spacing between fuel pins which then allows coolant flow by convection for decay heat removal, and since they do not react with water the heat exchanger interface is safer. They do not burn when exposed to air. However, they are corrosive of fuel cladding and steels, which originally limited temperatures to 550°C (boiling point of lead is 1750°C). With today's materials 650°C can be reached, and in future 800°C is envisaged with the second stage of Generation IV development, using oxide dispersion-strengthened steels. Lead and Pb-Bi have much higher thermal conductivity than water, but lower than sodium. Rosatom is building a demonstration 300 MWe BREST lead-cooled fast neutron reactor in Russia. Westinghouse is developing a lead-cooled fast reactor concept and LeadCold in Canada is developing one also, using novel aluminium-steel alloys that are highly corrosion-resistant to 450°C. The compound Ti3SiC2 (titanium silicon carbide) is suggested for primary circuits, resisting corrosion.

While lead has limited activation from neutrons, a problem with Pb-Bi is that it yields toxic polonium (Po-210) activation product, an alpha-emitter with a half-life of 138 days. Pb-Bi melts at a relatively low 125°C (hence eutectic) and boils at 1670°C, Pb melts at 327°C and boils at 1737°C but is very much more abundant and cheaper to produce than bismuth, hence is envisaged for large-scale use in the future, though freezing must be prevented. The development of nuclear power based on Pb-Bi cooled fast neutron reactors is likely to be limited to a total of 50-100 GWe, basically for small reactors in remote places. In 1998 Russia declassified a lot of research information derived from its experience with submarine reactors, and US interest in using Pb generally or Pb-Bi for small reactors has increased subsequently. The Gen4 Module (Hyperion) reactor will use lead-bismuth eutectic which is 45% Pb, 55% Bi. A secondary circuit generating steam is likely.

For details of lead-bismuth eutectic coolants, see the 2013 IAEA report in References.

SALT: Fluoride salts boil at around 1400°C at atmospheric pressure, so allow several options for use of the heat, including using helium in a secondary Brayton cycle circuit with thermal efficiencies of 48% at 750°C to 59% at 1000°C, for manufacture of hydrogen. Fluoride salts have a very high boiling temperature, very low vapour pressure even at red heat, very high volumetric heat capacity (4670 kJ/m3 for FLiBe, higher than water at 75 atm pressure), good heat transfer properties, low neutron absorbtion, good neutron moderation capability, are not damaged by radiation, are chemically very stable so absorb all fission products well and do not react violently with air or water, are compatible with graphite, and some are also inert to some common structural metals. Some gamma-active F-20 is formed by neutron capture, but has very short half-life (11 seconds).

Lithium-beryllium fluoride Li2BeF4 (FLiBe) salt is a eutectic version of LiF (2LiF + BeF2) which solidifies at 459°C and boils at 1430°C. It is favoured in MSR and AHTR/FHR primary cooling and when uncontaminated has a low corrosion effect. LiF without the toxic beryllium solidifies at about 500°C and boils at about 1200°C. FLiNaK (LiF-NaF-KF) is also eutectic and solidifies at 454°C and boils at 1570°C. It has a higher neutron cross-section than FLiBe or LiF but can be used intermediate cooling loops.

For details of molten salt coolants, both as coolant only and as fuel-carriers, see the 2013 IAEA report on Challenges Related to the Use of Liquid Metal and Molten Salt Coolants in Advanced Reactors – Report of the Collaborative Project COOL of the International Project on Innovative Nuclear Reactors and Fuel Cycles (INPRO).

Chloride salts have advantages in fast-spectrum molten salt reactors, having higher solubility for actinides than fluorides. While NaCl has good nuclear, chemical and physical properties its high melting point means it needs to be blended with MgCl2 or CaCl2, the former being preferred in eutectic, and allowing the addition of actinide trichlorides. The major isotope of chlorine, Cl-35 gives rise to Cl-36 as an activation product – a long-lived energetic beta source, so Cl-37 is much preferable in a reactor. In thermal reactors, chlorides are only candidates for secondary cooling loops.

All low-pressure liquid coolants allow all their heat to be delivered at high temperatures, since the temperature drop in heat exchangers is less than with gas coolants. Also, with a good margin between operating and boiling temperatures, passive cooling for decay heat is readily achieved. Since heat exchangers do leak to some small extent, having incompatible primary and secondary coolants can be a problem. The less pressure difference across the heat exchanger, the less is the problem.

The removal of passive decay heat is a vital feature of primary cooling systems, beyond heat transfer to do work. When the fission process stops, fission product decay continues and a substantial amount of heat is added to the core. At the moment of shutdown, this is about 6.5% of the full power level, but after an hour it drops to about 1.5% as the short-lived fission products decay. After a day, the decay heat falls to 0.4%, and after a week it will be only 0.2%. This heat could melt the core of a light water reactor unless it is reliably dissipated, as shown in the March 2011 accident at Fukushima Daiichi, where about 1.5% of the heat was being generated when the tsunami disabled the cooling. In passive systems, some kind of convection flow is relied upon. Decay heat removal is more of a problem in gas-cooled reactors due to low thermal inertia, and this has limited the size of individual units.

Heat transfer for different primary coolants used in nuclear power reactors

Note: low pressure liquid coolants allow more heat to be delivered at higher temperatures

Source: Forsberg

There is some radioactivity in the cooling water flowing through the core of a water-cooled reactor, due mainly to the activation product nitrogen-16, formed by neutron capture from oxygen. N-16 has a half-life of only 7 seconds but produces high-energy gamma radiation during decay. It is the reason that access to a BWR turbine hall is restricted during actual operation.

Load-following capability

Nuclear power plants are best run continuously at high capacity to meet base-load demand in a grid system. If their power output is ramped up and down on a daily and weekly basis, efficiency is compromised, and in this respect they are similar to most coal-fired plants. (It is also uneconomic to run them at less than full capacity, since they are expensive to build but cheap to run.) However, in some situations it is necessary to vary the output according to daily and weekly load cycles on a regular basis, for instance in France, where there is a very high reliance on nuclear power. Areva has developed its Advanced Load-Following Control System for PWRs that automatically adjusts the plant's electrical output according to the needs of the grid operator. It involves a software upgrade of the reactor control system which varies the plant's output between 50% and 100% of its installed capacity without intervention of the operator. Since 2008, Areva NP has installed the technology at four German nuclear power units, Philippsburg 2 (now shutdown), Isar 2, Brokdorf, and Grohnde, as well as Goesgen in Switzerland.

BWRs can be made to follow loads reasonably easily without burning the core unevenly, by changing the coolant flow rate. Load following is not as readily achieved in a PWR, but especially in France since 1981, so-called 'grey' control rods are used. The ability of a PWR to run at less than full power for much of the time depends on whether it is in the early part of its 18 to 24-month refuelling cycle or late in it, and whether it is designed with special control rods which diminish power levels throughout the core without shutting it down. Thus, though the ability on any individual PWR reactor to run on a sustained basis at low power decreases markedly as it progresses through the refuelling cycle, there is considerable scope for running a fleet of reactors in load-following mode. European Utility Requirements (EUR) since 2001 specify that new reactor designs must be capable of load-following between 50 and 100% of capacity with a rate of change of electric output of 3-5% per minute. The economic consequences are mainly due to diminished load factor of a capital-intensive plant. Further information in the Nuclear Power in France information page and the 2011 Nuclear Energy Agency report, Technical and Economic Aspects of Load Following with Nuclear Power Plants.

As fast neutron reactors become established in future years, their ability to load-follow will be a benefit.

Nuclear reactors for process heat

Producing steam to drive a turbine and generator is relatively easy, and a light water reactor running at 350°C does this readily. As the above section and Figure show, other types of reactor are required for higher temperatures. A 2010 US Department of Energy document quotes 500°C for a liquid metal cooled reactor (FNR), 860°C for a molten salt reactor (MSR), and 950°C for a high temperature gas-cooled reactor (HTR). Lower-temperature reactors can be used with supplemental gas heating to reach higher temperatures, though employing an LWR would not be practical or economic. The DOE said that high reactor outlet temperatures in the range 750 to 950°C were required to satisfy all end user requirements evaluated to date for the Next Generation Nuclear Plant.

Primitive reactors

The world's oldest known nuclear reactors operated at what is now Oklo in Gabon, West Africa. About 2 billion years ago, at least 16 natural nuclear reactors achieved criticality in a high-grade deposit of uranium ore (a 17th was in the Bangombe deposit 30 km away). Each operated intermittently at about 20 kW thermal, the reaction ceasing whenever the water turned to steam so that it ceased to function as moderator. At that time the concentration of U-235 in all natural uranium was about 3.6% instead of 0.7% as at present. (U-235 decays much faster than U-238, whose half-life is about the same as the age of the Earth. When the Earth was formed U-235 was about 30% of uranium.) These natural chain reactions started spontaneously and continued overall for one or two million years before finally dying away. It appears that each reactor operated in pulses of about 30 minutes. It is estimated that about 130 TWh of heat was produced. (The reactors were discovered when assays of mined uranium showed only 0.717% U-235 instead of 0.720% as everywhere else on the planet. Further investigation identified particular reactor zones with U-235 levels down to 0.44%. There were also significant concentrations of decay nuclides from fission products of both uranium and plutonium.)

During this long reaction period about 5.4 tonnes of fission products as well as up to two tonnes of plutonium together with other transuranic elements were generated in the orebody. The initial radioactive products have long since decayed into stable elements but close study of the amount and location of these has shown that there was little movement of radioactive wastes during and after the nuclear reactions. Plutonium and the other transuranics remained immobile.

References & notes

General sources

Wilson, P.D., The Nuclear Fuel Cycle, OUP (1996)

Alex P. Meshik, The Workings of an Ancient Nuclear Reactor, Scientific American (26 January 2009; originally published in the October 2005 edition of Scientific American)

Evelyn Mervine, Nature's Nuclear Reactors: The 2-Billion-Year-Old Natural Fission Reactors in Gabon, Western Africa, Scientific American (13 July 2011)

Technical and Economic Aspects of Load Following with Nuclear Power Plants, OECD Nuclear Energy Agency (June 2011)

International Atomic Energy Agency, Challenges Related to the Use of Liquid Metal and Molten Salt Coolants in Advanced Reactors – Report of the Collaborative Project COOL of the International Project on Innovative Nuclear Reactors and Fuel Cycles (INPRO), IAEA-TECDOC-1696 (May 2013)

References

1. C. W. Forsberg, P. F. Peterson and P. S. Pickard, Molten-Salt-Cooled Advanced High-Temperature Reactor for Production of Hydrogen and Electricity, Nuclear Technology, American Nuclear Society (May 2003)

RBMK Reactors Appendix to Nuclear Power Reactors

The Soviet-designed RBMK (reaktor bolshoy moshchnosty kanalny, high-power channel reactor) is a water-cooled reactor with individual fuel channels and using graphite as its moderator. It is also known as the light water graphite reactor (LWGR). As with a boiling water reactor (BWR), water boils in the fuel channels (at about 6.9 MPa) and steam is separated above them in a single circuit. It was designed over 1964-66 and is very different from most other power reactors. Its precursors were an experimental 30 MWt (5 MWe) LWGR at Obninsk which started up in 1954, and two small prototype LWGR (AMB-100 & 200) units – Beloyarsk 1&2, which ran from 1964 and 1968 respectively. (The ADE reactors at Zheleznogorsk and Seversk used for plutonium production are similar to the RBMK but with much lower power density and smaller fuel elements.)

The combination of graphite moderator and water coolant is found in no other power reactors in the world. As the Chernobyl accident showed, several of the RBMK's design characteristics – in particular, the control rod design and a positive void coefficient – were unsafe. A number of significant design changes were made after the Chernobyl accident to address these problems.

Features of the RBMK

Fuel

Pellets of slightly-enriched uranium oxide are enclosed in a zircaloy tube 3.65m long, forming a fuel rod. A set of 18 fuel rods is arranged cylindrically in a carriage to form a fuel assembly. Two of these end on end occupy each pressure tube.

Pressure tubes

Within the reactor each fuel assembly is positioned in its own vertical pressure tube or channel about 7 m long. Each channel is individually cooled by pressurised water which is allowed to boil in the tube and emerges at about 290°C.

Refuelling

When fuel channels are isolated, the fuel assemblies can be lifted into and out of the reactor, allowing fuel replenishment while the reactor is in operation.

Graphite moderator

A series of graphite blocks surround, and hence separate, the pressure tubes. They act as a moderator to slow down the neutrons released during fission so that a continuous fission chain reaction can be maintained. Heat conduction between the blocks is enhanced by a mixture of helium and nitrogen gas.

Control rods

Boron carbide control rods absorb neutrons to control the rate of fission. A few short rods, inserted upwards from the bottom of the core, even the distribution of power across the reactor. The main control rods are inserted from the top down and provide automatic, manual, or emergency control. The automatic rods are regulated by feedback from in-core detectors. If there is a deviation from normal operating parameters (e.g. increased reactor power level), the rods can be dropped into the core to reduce or stop reactor activity. A number of rods remain in the core during operation.

Coolant

Two separate water coolant loops each with four pumps circulate water through the pressure tubes to remove most of the heat from fission. There is also an emergency core cooling system which is designed to come into operation if either coolant circuit is interrupted.

Steam separator

Each of the two loops has two steam drums, or separators, where steam from the heated coolant is fed to the turbine to produce electricity in the generator (each loop has a turbogenerator associated with it). The steam is then condensed and fed back into the circulating coolant.

Containment

There is no secure containment in the sense accepted in the West. The reactor core is located in a reinforced concrete lined cavity that acts as a radiation shield. The core sits on a heavy steel plate, with a 1000 tonne steel cover plate on the top. The extensions of the fuel channels penetrate the lower plate and the cover plate and are welded to each. The steam separators of the coolant systems are housed in their own concrete shields.

Positive void coefficient

The term 'positive void coefficient' is often associated with RBMK reactors.

Reactors cooled by boiling water will contain a certain amount of steam in the core. Because water is both a more efficient coolant and a more effective neutron absorber than steam, a change in the proportion of steam bubbles, or 'voids', in the coolant will result in a change in core reactivity. The ratio of these changes is termed the void coefficient of reactivity. When the void coefficient is negative, an increase in steam will lead to a decrease in reactivity.

In those reactors where the same water circuit acts as both moderator and coolant, excess steam generation reduces the slowing of neutrons necessary to sustain the nuclear chain reaction. This leads to a reduction in power, and is a basic safety feature of most Western reactors.

In reactor designs where the moderator and coolant are of different materials, excess steam reduces the cooling of the reactor, but as the moderator remains intact the nuclear chain reaction continues. In some of these reactors, most notably the RBMK, the neutron absorbing properties of the cooling water are a significant factor in the operating characteristics. In such cases, the reduction in neutron absorption as a result of steam production, and the consequent presence of extra free neutrons, enhances the chain reaction. This leads to an increase in the reactivity of the system.

The void coefficient is only one contributor to the overall power coefficient of reactivity, but in RBMK reactors it is the dominant component, reflecting a high degree of dependence of reactivity on the steam content of the core. At the time of the accident at Chernobyl, the void coefficient of reactivity was so positive that it overwhelmed the other components of the power coefficient, and the power coefficient itself became positive. When the power began to increase, more steam was produced, which in turn led to an increase in power. The additional heat resulting from the increase in power raised the temperature in the cooling circuit and more steam was produced. More steam means less cooling and less neutron absorption, resulting in a rapid increase in power to around 100 times the reactor's rated capacity.

The value of the void coefficient is largely determined by the configuration of the reactor core. In RBMK reactors, an important factor affecting this is the operating reactivity margin.

Operating reactivity margin

Although the definition is not precise, the operating reactivity margin (ORM) is essentially the number of 'equivalent' control rods of nominal worth remaining in the reactor core. The operators at Chernobyl seemed to believe that safety criteria would be met so long as the lower limit for the ORM of 15 equivalent rods was adhered to, regardless of the actual configuration of the core. The operators were not aware of the 'positive scram' effect where, following a scram signal, the initial entry of the control rods actually added reactivity to the lower region of the core (see section below on Post accident changes to the RBMK).

The ORM could have an extreme effect on the void coefficient of reactivity, as was the case for the core configuration of Chernobyl 4 in the run-up to the accident. Unacceptably large void coefficients were prevented for initial cores by increasing fuel enrichment levels, with the excess reactivity balanced by fixed absorbers. However, with increasing fuel burn-up, these absorbers could be removed to maintain the fuel irradiation levels - shifting the void coefficient in the positive direction and increasing the sensitivity of the coefficient to the extent of insertion of the control and protection rods.

Post accident changes to the RBMK

After the accident at Chernobyl, several measures were taken to improve the safety of RBMK plants. All operating RBMK reactors in the former Soviet Union had the following changes implemented to improve operating safety:

- Reduction of the void coefficient of reactivity.

- Improvement of the response efficiency of the emergency protection system.

- Introduction of calculation programs to provide an indication of the value of the operating reactivity margin (ORM, i.e. the effective number of control rods remaining in the core) in the control room.

- Prevention of the emergency safety systems from being bypassed while the reactor is operating.

- In order to ensure adequate subcooling at the core inlet, the avoidance of modes of operation that cause a reduction in the departure from nucleate boiling (DNB) ratio of the coolant at the reactor inlet.

Measures to reduce the void coefficient of reactivity were carried out by:

- The installation of 80-90 additional fixed absorbers in the core to inhibit operation at low power.

- Increasing the ORM from 26-30 rods (in steady state operational mode) to 43-48.

- An increase in fuel enrichment from 2% to 2.4%.

The increase in the number of fixed absorbers and the ORM reduced the value of the void coefficient of reactivity to +ß (where ß is the effective delayed neutron fraction). The additional absorbers require the use of higher fuel enrichment to compensate for the increased neutron absorption.

The efficiency and speed of the emergency protection system was improved by implementing three independent retrofitting operations:

- Retrofitting of control rods with a design that does not give rise to water columns at the bottom of the channels.

- Scram (shut down) rod insertion time cut from 18 to 12 seconds.

- The installation of a fast-acting emergency protection (FAEP) system.

One of the most important post-accident changes to the RBMK was the retrofitting of the control rods. A graphite 'displacer' is attached to each end of the length of absorber of each rod (except for 12 rods used in automatic control). The lower displacer prevents coolant water from entering the space vacated as the rod is withdrawn, thus augmenting the reactivity worth of the rod. However, the dimensions of the rod and displacers were such that, with the rod fully withdrawn, the 4.5 m displacer sat centrally within the fuelled region of the core with 1.25 m of water at either end. On a scram signal, as the rod falls, the water at the lower part of the channel is replaced by the bottom of the graphite displacer, thus initially adding reactivity to the bottom part of the core. Following the Chernobyl accident, this 'positive scram' effect was mitigated by retrofitting the control rods so that, with the rods fully retracted, there would not be a region containing water at the bottom of the core.

The FAEP system was designed so that 24 emergency protection control rods would insert negative reactivity of at least 2ß in under 2.5 seconds. Tests in 1987-'88 at the Ignalina and Leningrad plants (the first RBMKs to be fitted with the new FAEP system) confirmed these characteristics.

In addition to the above changes, several further modifications have been implemented at RBMK plants. These measures consist of:

- Replacement of the fuel channels at all units (except Smolensk 3).

- Replacement of the group distribution headers and addition of check valves.

- Improvements to the emergency core cooling systems.

- Improvements of the reactor cavity over-pressure protection systems.

- Replacement of the SKALA process computer.

Operating RBMK plants

There are currently eight operating RBMKs, all of which are in Russia. One more was under construction in Russia (Kursk 5), but it is now cancelled. All operating RBMKs began operation between 1979 (Kursk 2) and 1990 (Smolensk 3). There are three distinct generations of RBMK reactors having significant differences with respect to their safety design features:

- The four first-generation units are Leningrad 1&2 (both now shutdown), and Kursk 1 (now shutdown) and 2. They were designed and brought online in the early-to-mid-1970s, before new standards on the design and construction of nuclear power plants, the OPB-82 General Safety Provisions, were introduced in the Soviet Union in 1982.

- Second-generation RBMKs, brought online since the late 1970s and early 1980s include Leningrad 3&4; Kursk 3&4; Ignalina 1 (now shutdown); and Smolensk 1&2. Ignalina 2 (now shutdown) had safety features beyond those of other second generation units. These units conform to the OPB-82 standards.

- After the Chernobyl accident, Soviet safety standards were revised again (OPB-88). One RBMK (Smolensk 3) has been built to these third-generation standards. Additional design changes were being incorporated in the construction of Kursk 5 before it was cancelled.

In 2006, Rosatom said it was considering operating lifetime extensions and uprating of its operating RBMK reactors. Following significant design modifications made after the Chernobyl accident, as well as extensive refurbishment including replacement of fuel channels, a 45-year operating lifetime is seen as realistic for the 1000 MWe-class units. In 2021, they provided about 25% of Russia's nuclear-generated electricity.

In the Table below, the 'operating until' dates are the scheduled shutdown for these plants, with 15-year lifetime extensions in some cases. Lithuania, on the other hand, closed Ignalina 1&2 early as a condition for entry into the European Union.

Russia's long-term plans had earlier included the possibility of replacing the Leningrad units, at the end of their extended service life, by new MKER-1000 units. These are a modification of the RBMK design. The main differences are in the spacing of the graphite lattice in the core and the incorporation of passive safety systems.

RBMK reactors

| Location | Unit | First power | Unit net capacity (MWe) | Status |

| Lithuania | ||||

| Ignalina | 1 | 1983 | 1185 (originally 1300) | Closed 12/2004 |

| 2 | 1987 | 1185 (originally 1300) | Closed 12/2009 | |

| Russia | ||||

| Kursk | 1 | 1976 | 925 | Closed 12/2021 |

| 2 | 1979 | 925 | Operating until 2024 | |

| 3 | 1984 | 925 | Operating until 2029 | |

| 4 | 1986 | 925 | Operating until 2031 | |

| 5 | - | Construction cancelled | ||

| Leningrad | 1 | 1973 | 925 | Closed 12/2018 |

| 2 | 1975 | 925 | Closed 11/2020 | |

| 3 | 1979 | 925 | Operating until 2025 | |

| 4 | 1981 | 925 | Operating until 2026 | |

| Smolensk | 1 | 1983 | 925 | Operating until 2028 |

| 2 | 1985 | 925 | Operating until 2030 | |

| 3 | 1990 | 925 | Operating until 2050 | |

| Ukraine | ||||

| Chernobyl | 1 | 1977 | 925 | Closed 1996 |

| 2 | 1978 | 925 | Closed 1991 | |

| 3 | 1981 | 925 | Closed 2000 | |

| 4 | 1983 | 925 | Reactor destroyed April 1986 | |

| 5 | - | 925 | Construction cancelled | |

| 6 | - | 925 | Construction cancelled | |

References & notes

General sources

INSAG-7, The Chernobyl Accident: Updating of INSAG-1, A report by the International Nuclear Safety Advisory Group, International Atomic Energy Agency, Safety Series No. 75-INSAG-7, 1992, (ISBN: 9201046928). See especially: Annex I of INSAG-7, the Report by a Commission to the USSR State Committee for the Supervision of Safety in Industry and Nuclear Power (SCSSINP); and Annex II of INSAG-7, the Report by Working Group of USSR Experts, Causes and Circumstances of the Accident at Unit 4 of the Chernobyl Nuclear Power Plant and Measures to Improve the Safety of Plants with RBMK Reactors (Moscow, 1991)

Fonte: World Nuclear Association

Collegati

Advisory Material for the IAEA Regulations for the Safe Transport of Radioactive Material

Regolamento IAEA sicurezza trasporti dei materiali radioattivi 2018 - Traduzione in IT

IAEA 2020 | Actions Taken at Nuclear Power Plants Fukushima Accident

I referendum abrogativi del nucleare del 1987

Chernobyl: 26 Aprile 1986

Scala internazionale degli eventi nucleari - Scala INES